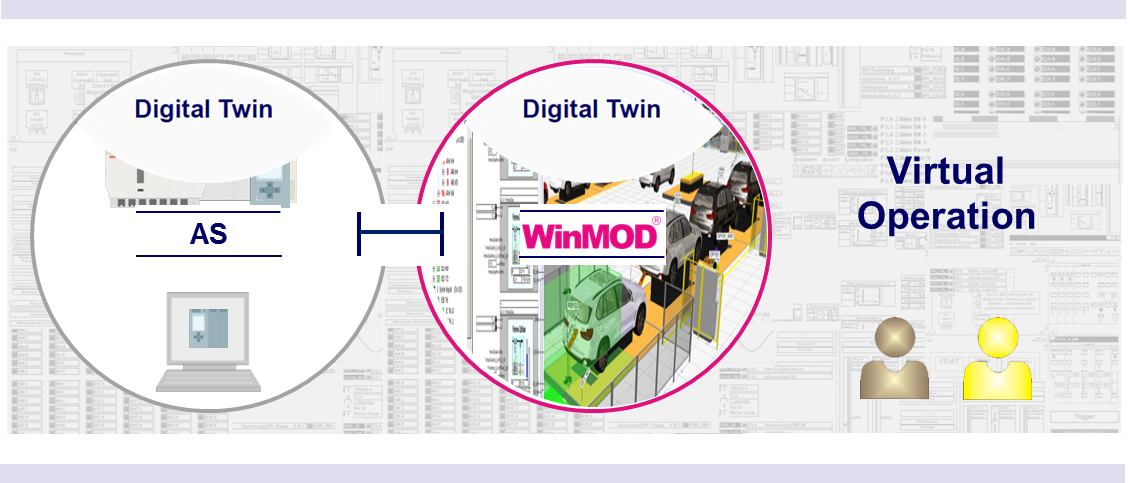

Virtual Operation

After commissioning the real machine/plant, the virtual machine/plant is available for further use. Service processes can be supported independently of the location of the machine/system and optimizations can be prepared during operation.

Digital Twin or Shadow Plant

When a real or virtual automation system in conjunction with a virtual plant is operated permanently parallel to the real plant, this is called a Digital Twin or a Shadow Plant. During operation of the plants, optimizations or process changes can be prepared without standstill and without endangering the real plant. Particular attention should be paid to the constant adaptation of the shadow system regarding the structure and behaviour of the real system. This allows a constant comparison between real and virtual behaviour. The Digital Twin supports the implementation of migrations. This is especially true when replacing automation systems with extreme requirements for recommissioning during operation of the system.