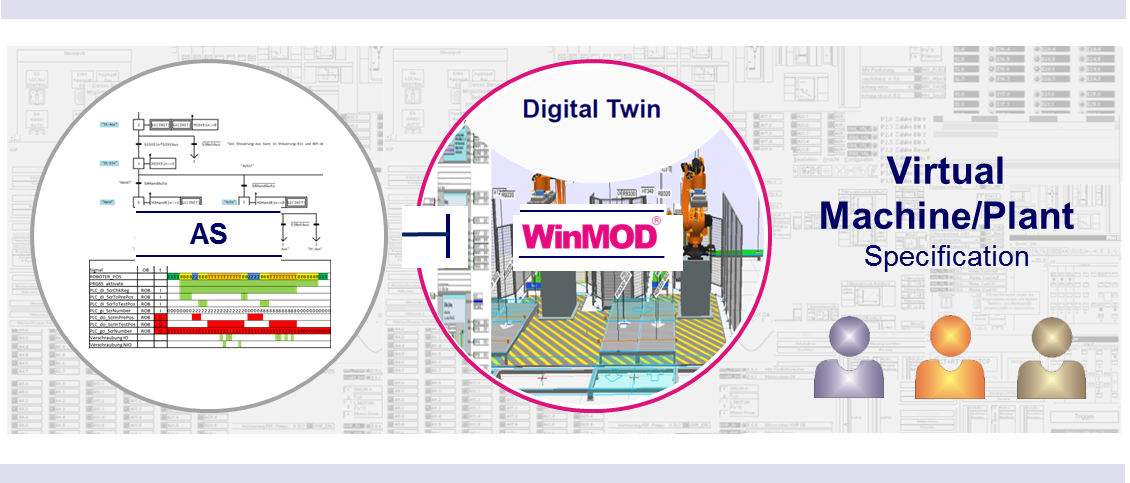

Virtual Machine/Plant

The virtualization of machines and systems is a composition and extension of the system simulation. The result is a model that corresponds in terms of behaviour and communication to reality so far that it can be connected to a real automation system without software modification and put into operation.

Since 1991, the WinMOD System Platform has been developed for achieving these goals. In 2002, the first prototype for a virtual machine tool was created. Then in 2005, the virtual system was part of a specification for the Virtual Commissioning of a manufacturing cell in the automotive industry.

For virtualization in process automation, the WinMOD System Platform has been gradually expanded to include industry-specific and technology-specific libraries, which provide the necessary depth of simulation for holistic modelling. To work with specialized simulation tools, WinMOD communications are used for integration into a runtime system.

For the virtualization in factory automation, the WinMOD System Platform has been expanded to include the system modules for WinMOD-SIMLINE with 3D visualization and the technology libraries with material flow capability. This allows machines and systems to be virtualized for all users from the automation point of view.

The virtualization itself creates the first benefit. The result is a functional specification from the point of view of the automation engineer. Defects and errors are detected early and corrected. For all further uses, a communication platform is available that is perceived and understood in the same way by all participants.

The virtual machines/systems are created in the WinMOD Project from the engineering data of the upstream or parallel engineering processes and must be kept consistent.

Realization with WinMOD:

- for the WinMOD Systems there is a clear concept for the modelling of virtual machines/plants

- engineering data from upstream or parallel tool are forwarded as far as possible

- many years of experience gained from previous uses are the basis for the further development of innovative technology

- Industry 4.0 thus receives the means to safeguard the functional quality and to make functions transparent and perceptible

- the extraction of engineering data is largely supported by assistants

Achievable Results:

- the virtual machines/systems are a functional image that is perceived and interpreted in the same way by all participants

- they help to avoid coordination mistakes and overcome boundaries between different trades

- in contrast to textual descriptions, they are clearer and show the dynamic behaviour

- the virtual machines/systems are the medium for the functional presentation