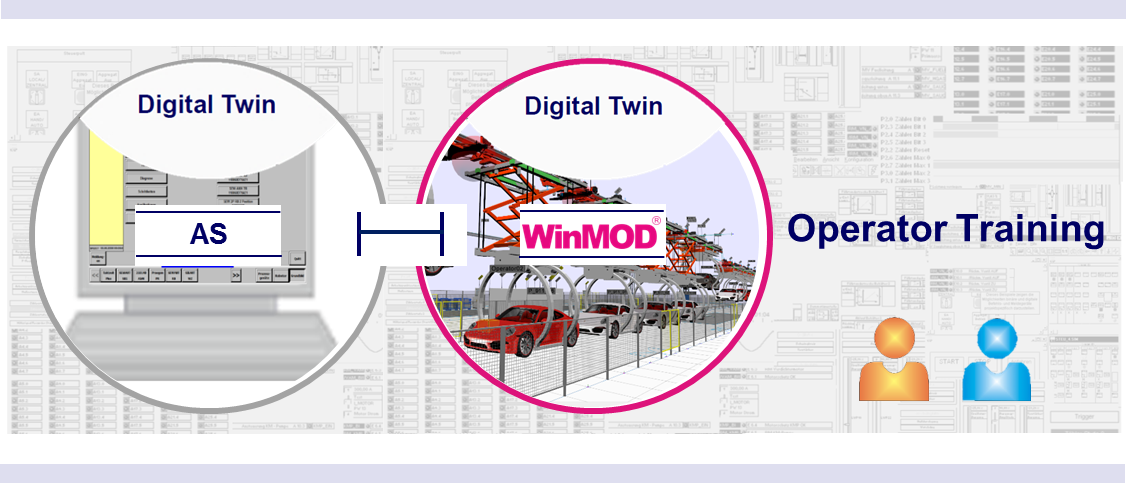

Operator Training

The plant simulation created for the commissioning can be further used for the operator training and enriched with training practical scenarios.

With a training simulator, the operation of automation systems is trained independently of the real plant. This task arises in new plants, for example, to be able to carry out the training parallel to the installation of the real automation system. Incidents and critical startup and shutdown processes can be safely transmitted to the operating personnel at the original user interface. Even language barriers are easier to bridge.

After the system has been commissioned, the same system platform can be maintained as a shadow system to repeat training sessions for new participants. It is also possible to replace the real automation system with a PC-based virtual system, e.g. with PLCSIM and WinCC. Thus, the system costs can be greatly reduced.

Realization with WinMOD:

- For the training request, the WinMOD Project is extended so that the process behaviour is sufficiently modelled.

- The plant simulation becomes a virtual plant.

- With the WinMOD Net Communication, the project parts can be distributed to several PCs without any loss of performance.

- The big advantage of the concept is the gradual deepening of the simulation project from its use in software testing, through FAT and up to training.

- It is always possible to work with the original automation software.

Achievable Results:

- Ensuring the qualification of operating and service personnel becomes part of quality assurance with an important social component.

- Stress and tricky situations can be trained in advance.

- It creates the conditions to meet new requirements and to ensure technological safety.