Factory Acceptance Test (FAT)

In process automation, the Factory Acceptance Test has been established long back in project management. The switches and lights originally connected to the software test have been replaced since 1995 by WinMOD Systems and the test depth has been increased.

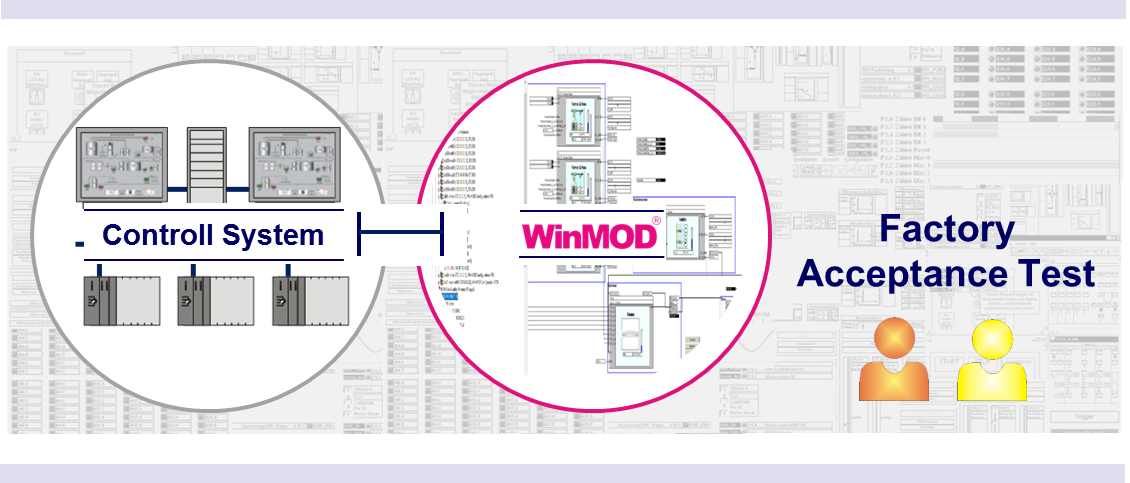

The test environment consists of the real control and guidance systems and a device periphery emulated with the WinMOD System. The behaviour of the system and the process components is simulated as far as required and agreed for the performance of the test (see also system simulation). This test environment dramatically reduces overhead compared to real peripheral testing while increasing test depth.

Realization with WinMOD:

- With the WinMOD System Software, the requirements for the simulation depth and the user interface can be completely covered.

- The preparation of libraries, the use of design standards, and the use of WinMOD Engineering Assistance minimize the engineering overhead of creating the WinMOD Project.

- Software Test and FAT complement each other for quality assurance according to the state of the art.

Achievable Results:

- Early detection of software failures, risk reduction, and test performance regardless of location and completion of the physical asset have resulted in significant improvements in project execution and economic conditions for both the software supplier and the client.

- Due to these achievable results, the FAT with WinMOD has become an integral part of many tenders.