WinMOD Configurations

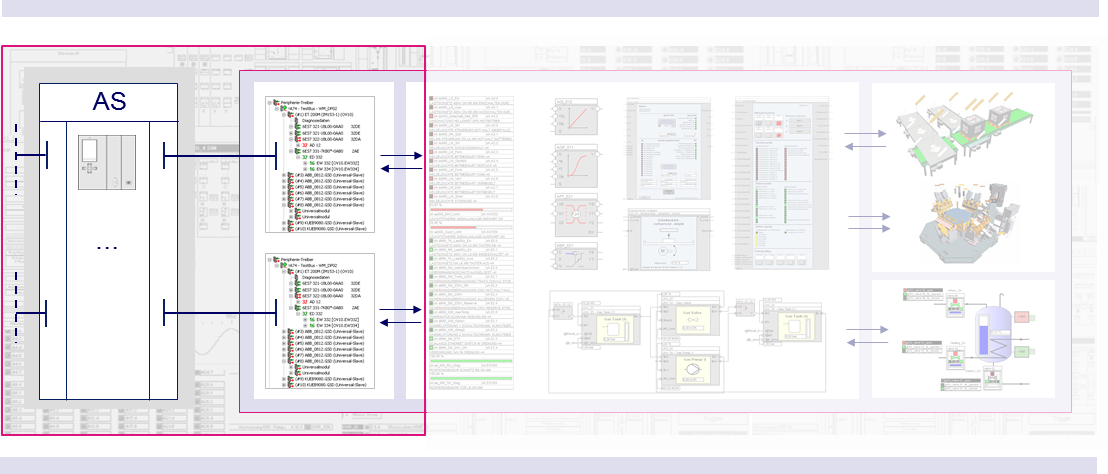

The WinMOD Configurations connect the automation system by different manufacturers to WinMOD Systems. The outstanding features are real-time performance, the combinability and scalability from small to large WinMOD Projects.

The available WinMOD Configurations enable the virtual connection of all standard automation systems (AS). For each AS product, several configurations are available for different operating conditions. For the selection of configuration, it is recommended to take advise from the WinMOD Team. The goal in selecting the WinMOD Configurations must have best possible performance in run mode and avoidance of software changes in AS. It is possible for connected AS to transmit cyclic, acyclic and safety signal.

WinMOD Configurations connect the automation system by different manufacturers to WinMOD Systems. The outstanding features are real-time performance, the combinability and scalability from small to large WinMOD Projects.

Configuring the WinMOD Configuration

The connection between the project in AS system and the project in WinMOD System can transmit several thousand signals. The WinMOD Configurations provide assistance functions to assist in editing. They use existing engineering data:

- from the programming system of AS

- from the planning tools (E-Plan)

- from the user-specific database mapping

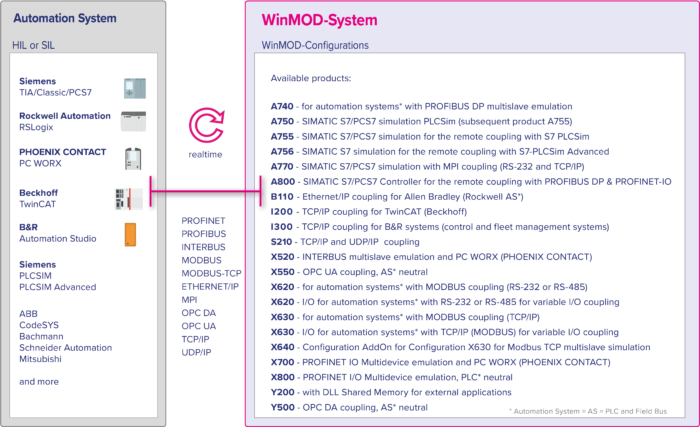

Currently available WinMOD configurations

- A710 for PROFIBUS normslave emulation

- A720 for SIMATIC S7/PCS7 simulation of S7-4xx central periphery

- A740 for automation systems with PROFIBUS DP Multislave emulation

- A750 for SIMATIC S7/PCS7 simulation PLCSIM (subsequent product A755)

- A755 for SIMATIC S7/PCS7 simulation for Remote Coupling with S7 PLCSIM

- A756 for SIMATIC S7 simulation for Remote Coupling with S7 PLCSIM Advanced

- A760 for PROFIBUS master emulation

- A770 for SIMATIC S7/PCS7 simulation with MPI coupling (RS-232 and TCP/IP)

- A780 for SIMATIC S7/PCS7 simulation with PROFIBUS DP & PROFINET IO (release until SIMULATIONUnit version 8.x) – subsequent product A800

- A800 for SIMATIC S7/PCS7 Controller with PROFINET IO/ PROFIBUS DP

- B100 for EtherNET/IP coupling for Allen Bradley (Rockwell AS) SLC

- B110 for EtherNET/IP coupling for Allen Bradley (Rockwell AS)

- B120 for EtherNET/IP Multislave emulation

- C250 for ETHERCAT Multislave emulation

- I200 for TCP/IP coupling for TwinCAT (Beckhoff)

- I300 for TCP/IP coupling for B&R systems (control and fleet management systems)

- S210 for message-oriented communication with TCP/IP, UDP/IP and RFC1006

- X510 for INTERBUS Multislave emulation and CMD (PHOENIX CONTACT)

- X520 for INTERBUS Multislave emulation and PC WORX (PHOENIX CONTACT)

- X550 OPC UA

- X620 for automation systems with MODBUS coupling (RS-232 or RS-485)

- X620 I/O for automation systems with RS-232 or RS-485 for variable I/O coupling

- X630 for automation systems with MODBUS coupling (TCP/IP)

- X630 I/O for automation systems with TCP/IP (MODBUS) for variable I/O coupling

- X630 Configuration Add-on for Modbus TCP Multidevice emulation

- X700 for PROFINET IO Multidevice-Emulation and PC WORX (PHOENIX CONTACT)

- X800 PROFINET IO Multidevice-Emulation, PLC neutral

- Y200 with DLL Shared Memory for external applications

- Y200 Configuration Add-on for Excel

- Y500 OPC DA

Integration of the WinMOD Configuration into project settlement

In the WinMOD Project, the WinMOD Configurations are described as the structure of simulated field devices. In the first part of WinMOD Project, every signal in the WinMOD System Software can be connected to a configurable WinMOD Signal Element. Therefore, the signal value can be visualized and can be actively adjusted to the appropriate setting.

Scaling

WinMOD Systems can be connected to multiple communication channels with appropriate communication equipment. They can be from similar or different WinMOD Configurations. In communication with the scalability and multi-instance capability of the WinMOD System Software, task-specific, very complex and large-scale WinMOD Projects can be realized.

Development

The WinMOD Configurations belong to core competence in WinMOD System Platform. The development of WinMOD Configuration is given by

- new neutral communication profiles such as OPC UA, PROFINET via TSN and many more

- new manufacturer specific communication for the Virtual Commissioning (for ex. Simulation Unit)

- new possibilities for data exchange with the engineering tools of the AS manufacturers (e.g. TIA openness) or AML-based configuration data

The resulting development requirements in terms of feasibility, real-time capability and performance are significant. The selection of WinMOD Configurations for the project specific requirements must be consulted by WinMOD Consultants to ensure the feasibility and selection of best conceptual configuration.

Information about new configurations or updates can be found under the menu item News. For more information please contact our WinMOD Team.