Robotics & pick-and-place systems

Factory automation solutions from WinMOD

robotics

Integration of industrial robots into the VC

Industrial robots and robotic tools

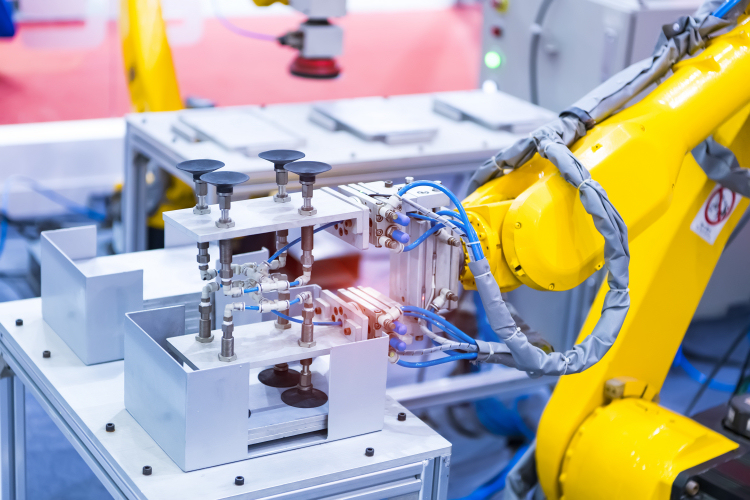

Industrial robots are a core technology in many areas of technology and are offered by many different robot manufacturers. They are divided into the general types Delta, SCARA, 6-axis and Cartesian. For virtual commissioning (VC), we therefore offer a large number of 3D robot libraries from well-known manufacturers. The basis is formed by many 6-axis articulated arm robots, but specialised models such as palletisers with compensation mechanisms or small robots for pick-and-place applications of small parts are also available.

From welding cells to component assembly, WinMOD-SIMLINE naturally also offers a wide range of parameterisable 3D elements for tilting, rotating and clamping devices, consoles, linear axes and tool changing systems. It is also possible to enhance these devices with individual 3D CAD data in order to integrate tailor-made solutions. 3D piece goods detection is performed by WinMOD-SIMLINE 3D sensor technology, which ensures accurate detection of objects in real time.

Robots via co-simulation

For the seamless integration of industrial robots into automated production processes, it is necessary to test not only the automation system but also the robot programmes. Many robot manufacturers offer their own simulation software for this purpose, in which one or more robots can be run with the original code. In cooperation with many robot manufacturers, we have online connections to these simulation tools and can exchange axis data and communication signals in real time with WinMOD.

This concept of CoSimulation makes VC of production processes with Robotics very efficient and meaningful. All communication between the robot and the plant control system is tested at a very early stage. All findings from offline programming (OPL) are thus incorporated directly into the VC.

If no robot programmes are available for a software test, this is not a problem. With WinMOD's own simulation concept Robcase, you can create and run robot sequences directly in our software.

Pick-and-place systems

Automatic component handling and manufacturing processes

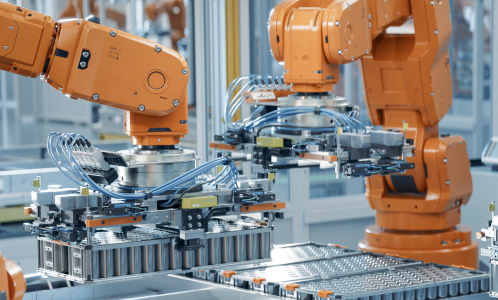

Pick-and-place with robots and gantry systems

The main components of this technology area are the handling units. Today, more and more classic industrial robots are being used here, ranging from small to large and from a wide variety of robot manufacturers. For virtual commissioning (VC), we therefore offer a large number of 3D robot libraries from well-known manufacturers.

Portal systems are another important technology. These are often highly customised in-house developments by plant suppliers. Our 3D multi-axis portals can therefore be freely configured in terms of size, shape and axis configuration. Of course, you can also import the CAD design data for your individual portal system. In our 3D editor, you have the option of preparing this data for simulation and defining travel paths, reference points, and pivot points. After all, these CAD-based systems should behave in VC in the same way as they do in reality.

Peripherals, sensors & data acquisition

The second important part for optimal VC is the simulation of the various peripheral devices. These are essentially gripping technologies such as vacuum suction cups, centric or magnetic grippers in all possible variations. For the design aspect, the 3D CAD data can also be imported directly here. These are supplemented by feeding systems such as roller conveyors, feeders or buffers, which you can integrate directly from our 3D conveyor technology libraries.

The third area comprises sensors and devices for data acquisition, such as force and torque sensors, 2D/3D cameras for position detection, Quality control and component classification. Here, too, there are extensive WinMOD libraries with virtual devices that simulate exactly the real behaviour relevant to control.

Finally, all virtual devices and systems are connected to the robot and plant controls and put into operation virtually as a complete system. All typical processes, from SMT assembly, packaging and sorting, case packing, e-commerce picking to machine assembly, can be simulated with the WinMOD-SIMLINE system.

Further factory automation solutions

Sorting and picking systems for small items such as cartons, plastic boxes or other piece goods. Transport is via classic roller conveyors, belt conveyors

as well as the typical cam roller conveyors found here,

Belt curves and accumulation roller conveyors.

This area of technology encompasses conveyor systems that transport and sort pallets and mesh boxes. The conveyor elements are large roller and chain conveyors combined with lifting, rotating and shifting tables. Magazines for empty pallets are also typical here.

These systems are usually fully automated high-bay warehouses that are operated by storage and retrieval machines and controlled by distributed automation systems. Warehouse management systems generate the orders for storage and retrieval.

Automated systems that pick up parts from A to B and place them down again with a defined orientation – typically for loading, sorting, picking or packing. Core systems are industrial robots (Delta, SCARA, 6 axes, Cartesian) or gantry axes.

Robotics plays a central role in modern manufacturing by enabling the automation of production processes and increasing efficiency and precision. Robots are used in various areas, such as welding, assembly, painting or packaging products.

Production lines combine processes, material flow and controls into a production system with guaranteed cycle times and quality. They consist of combinations of assembly, processing and testing stations. In addition, there is transfer technology, buffers and often a highly specialised automation system.

Electric Monorail Systems are used as connecting conveyor technology over long distances. The overhead trolleys run fully automatically with integrated electric drives and controls and are usually routed via a central control system.

This chain-driven overhead or floor conveyor technology is powered by continuously running power strands (chains). Transport trolleys are coupled in, transported, decoupled at stoppers and buffered via chain drivers („dogs“).

Automated self-driving vehicles as a connecting material flow solution. Driving is either completely trackless via defined tracks or markers (AGV) or via free navigation with automatic dynamic obstacle avoidance (AMR).

Engineering discipline for the development, manufacture and maintenance of machines, plants and production systems. Typical applications include machine tools, handling technology, automotive/aerospace, packaging and assembly plants.