Testing systems and software in virtual space

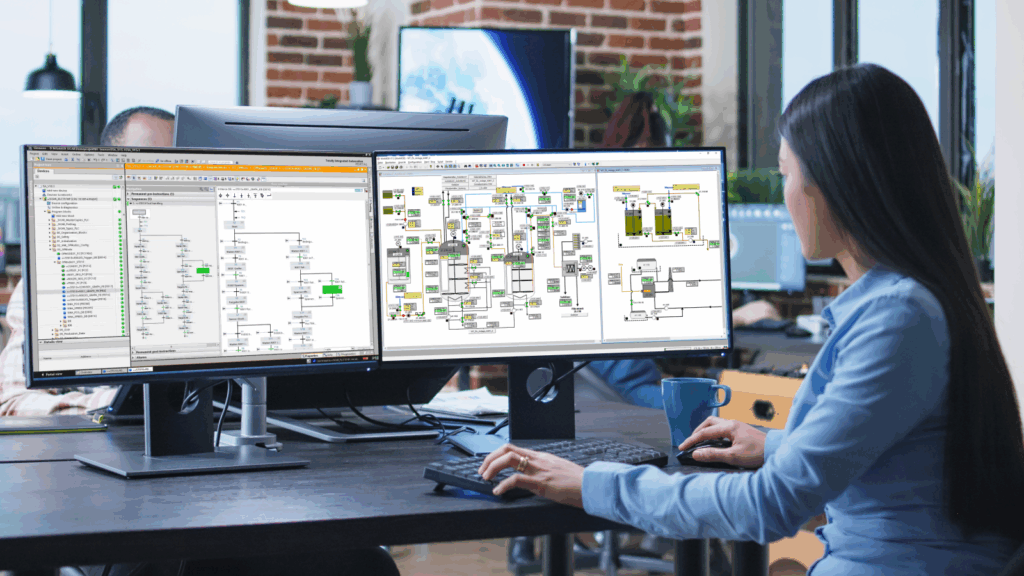

Systems and processes simulated in WinMOD allow extensive and individual testing of control software.

software test

Test the control programme under realistic but risk-free conditions and check it thoroughly for inconsistencies independently of the real machine.

plant simulation

Extended software testing through the combination of real-time behavioural simulations and manual interventions in the WinMOD simulation.

Factory acceptance test

Conducting the FAT using a virtual simulation of the entire automation system to identify errors before the real test.

software test

Test the control programme under realistic but risk-free conditions and check it thoroughly for inconsistencies independently of the real machine.

Comprehensive and system-independent software testing

Software testing is essential for software quality. WinMOD systems create the conditions for efficient software testing, independent of the actual plant and with the necessary depth of testing.

The WinMOD system can be connected to a real AS (HIL) or a virtual AS (SIL). The large number of available WinMOD configurations makes it possible to connect automation systems from different manufacturers at a single workstation and with a single WinMOD test project.

Software testing with I/O simulation

The software test can refer to individual function controls in the AS or to the entire AS project. With the WinMOD configurations, process images can be configured quickly and easily with WinMOD signals. The WinMOD signal elements visualise the signal values with parameterisable displays. The signal values can be forced manually and spontaneously. Forcemachine and script generator are available for predefined test sequences.

Software testing with fieldbus emulation

For the WinMOD system, there are WinMOD configurations, e.g. for PROFIBUS / INTERBUS / PROFINET, which emulate the fieldbus with the projected bus configuration. Cyclic signals, acyclic signals and safety signals are transmitted. In the WinMOD project, the transmitted signals can be graphically structured and assigned to the fieldbus devices. The device and process behaviour is then simulated in the WinMOD project to the extent necessary for the software test.

plant simulation

Extended software testing through the combination of real-time behavioural simulations and manual interventions in the WinMOD simulation.

Test behavioural simulations in real time

The use of plant simulations is an extension of the simulation depth for software testing. It is typically a combination of real-time behavioural simulations and manual interventions in the WinMOD project.

System simulation for more in-depth software testing

Plant simulation is used in software engineering when WinMOD systems are utilized for in-depth software testing of automation systems. This extends the depth of testing. The test sequences can be repeated under the same conditions. The scope of plant simulation depends on knowledge of plant behaviour. The simulation depth corresponds to the requirements for software testing and for the Factory Acceptance Test (FAT).

The connection to the control system is established via WinMOD configurations.

Clear coordination creates commitment

When coordinating between the client and contractor regarding the tests to be carried out, the user interface, structure and simulation depth should be agreed upon. Further expansion of the plant simulation can lead to a training model, shadow plant or virtual machine/plant.

The digital twin as the key to migrations

The digital twin supports the implementation of migrations. This applies in particular to the replacement of automation systems with extreme requirements for recommissioning while the plant is in operation.

Factory acceptance test

Conducting the FAT using a virtual simulation of the entire automation system to identify errors before the real test.

Factory Acceptance Test (FAT)

In process automation, factory acceptance testing has long been established in project management. The switches and lights originally connected for software testing were replaced by WinMOD systems in 1995, and the depth of testing was increased.

The test environment consists of the actual control and monitoring systems and device peripherals emulated using the WinMOD system. The behaviour of the plant and the process components is simulated to the extent necessary and agreed upon for the test (see also Plant Simulation). This test environment drastically reduces the effort required compared to tests with real peripherals, while at the same time increasing the depth of testing.

Implementation with WinMOD

- The WinMOD system software fully covers the requirements for simulation depth and user interface.

- Preparation of libraries, use of design standards and use of the WinMOD Engineering Assistant minimise the engineering effort required to create the WinMOD project.

- Software testing and FAT complement each other to provide state-of-the-art quality assurance.

- Early detection of software errors, risk reduction and testing independent of location and completion of the actual plant bring clear improvements in project workflow and economic conditions for both the software supplier and the client.

- FAT with WinMOD has become an integral part of many tenders.

Would you like to work with us?

We are happy to advise and support you with your first project. After a short online introduction, you can get started with WinMOD right away and test it out.

Just give us a call!

Do you require assistance?

If you have any questions, problems or other concerns, our support team is here to help. You will also find helpful instructions and downloads in our support section.