pressing plants

Fabrication of structural car body parts from sheet metal coils

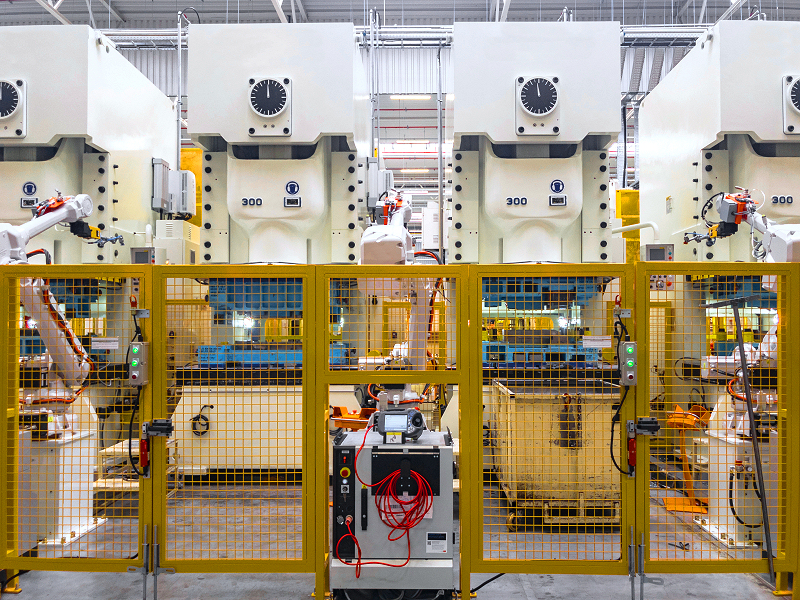

Tandem press lines

Press shops use highly dynamic presses to form blanks into precise body and structural parts. There are presses, conveyor lines and industrial robots with a high degree of Automation and tightly synchronised process windows. When performing virtual commissioning (VC) of press lines, it is therefore essential to test the interaction of these systems. For conveyor technology, the WinMOD-SIMLINE system offers a wide range of roller conveyors, chain conveyors, rotary, lifting and travelling carriages as 3D elements. For the associated drive technology, there are virtual device libraries that simulate the control-relevant behaviour. Many different 3D robot libraries and 3D portal systems are available for feeding and discharging by robots or transfer axes.

The virtual body parts and coils run along the 3D conveyor belts and are precisely detected by 3D sensors and loaded into the presses by robots or transfer axes.

For VC, the individual controllers are then connected to the WinMOD system via fieldbus and the virtual devices are wired with the PLC signals. This allows the entire material flow in press lines to be put into operation virtually in real time.

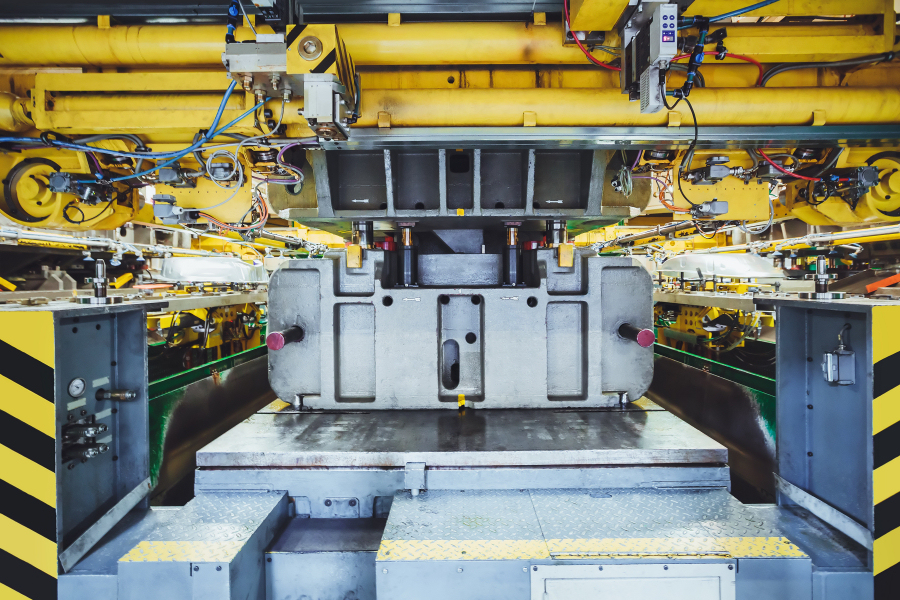

Pressing and material processes

When it comes to the actual pressing and material processes, the focus is naturally on completely different processes such as cold and hot forming or deep drawing behaviour in the individual press stations. WinMOD is not a system for performing FEM-based forming simulation, as there are special tools available for this purpose that have completely different requirements as offline simulations. However, you can integrate the results, i.e. press functions or data sets of the travel curves, into WinMOD. Real-time simulation provides you with realistic press times and allows you to test their influence on the entire system, for example.

For 3D visualisation of your presses, you can import their 3D CAD data, edit it in the WinMOD-SIMLINE 3D editor and connect the moving parts to the online axis values. For thermal processes, you can again utilize elements from the WinMOD libraries. These are virtual pumps, valves, heating elements, pressure vessels and temperature sensors, which you can combine to form control systems and which then exchange their values and states with the control system, just as in reality.

Further automotive engineering solutions

Production area in which structural body parts and outer skin parts are produced from sheet metal coils or cut-to-size blanks (blanks) by cold or hot forming – from the raw blank to the ready-to-install formed part.

Assembles stamped/formed sheet metal parts, extruded and cast components into a dimensionally accurate body structure – with defined geometry, rigidity, crash and NVH performance as the basis for the paint shop and final assembly.

Highly automated plant chains for surface pre-treatment, coating and curing of car bodies and add-on parts – designed for high throughput, reproducible appearance and corrosion protection.

Pre-assembly of front/rear axle modules as carriers for chassis, steering and drive units such as combustion engines, powertrains or electric axles. Transport to the sequenced handover to the „marriage“ with the body.

Highly automated process chain for the fabrication of traction batteries – from electrode production to cell assembly and forming to module/pack assembly

This area of technology encompasses conveyor systems that transport and sort pallets and mesh boxes containing automotive components. The conveyor elements are large roller and chain conveyors combined with lifting, rotating and shifting tables.

Fully automated high-bay warehouses, which are operated by light or heavy-duty storage and retrieval machines and controlled by distributed automation systems. Warehouse management systems generate the orders for storing and retrieving raw components or complete car bodies.

Ground-based conveyor technology in which car bodies or heavy modules are transported on standardised SKIDs (steel frames with vehicle-specific support points) through assembly, paint shop and buffer areas.

Overhead conveyor systems with electrically driven, individually controllable trolleys on monorail tracks for low or high loads (up to tonnes).

Ground-based conveyor technology in which car bodies or heavy assemblies are moved on platforms along rails. The drive is typically provided by friction wheels, push chain conveyors or push beams, which continuously push the SKIDs forward.