add-ons

Our open data interfaces guarantee maximum flexibility, seamless integration and future-proof networking of your systems.

Engineering Assistant

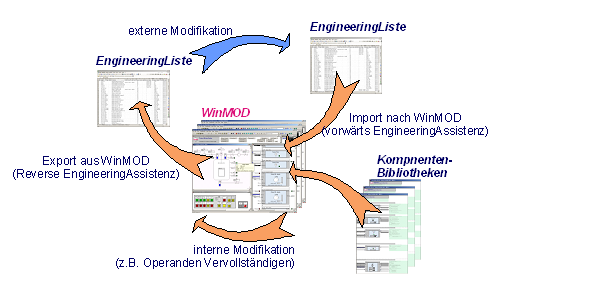

The Engineering Assistant automatically creates WinMOD projects based on existing engineering data. Once the data format has been defined, libraries prepared specifically for the technology and company can be interconnected on a project-specific basis in accordance with existing engineering data.

This automatic process ensures that changes to engineering data are applied quickly and consistently at all times. All engineering data used is checked for consistency, contradictions and errors.

This ensures that the WinMOD simulation always corresponds exactly to the engineering data – efficiently, error-free and fully integrated into project management.

Your advantages:

- Automatic generation of the simulation from existing engineering data

- Significantly reduced manual effort

- High consistency between WinMOD and external data

- Quick and easy updating in case of changes

recorder

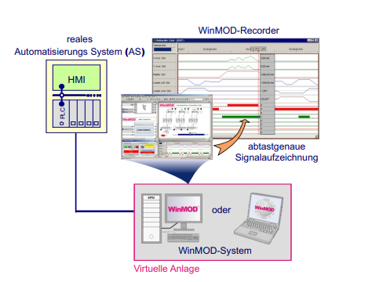

The recorder records all signal curves and displays them graphically or imports them from open data interfaces. This allows processes to be monitored in real time during simulation, then analysed in detail or compared with target values. Recorded data is permanently available and can be exported as graphics or raw data.

Operation is intuitive and can be customised at any time. Freely definable triggers allow multiple recorders to be created in parallel with different sampling rates and data sources.

The recorder offers versatile analysis options across the entire life cycle of plants and machines. Whether using signal and difference cursors or time marks, the dynamic behaviour of a plant can be precisely examined and efficiently evaluated.

Your advantages:

- Real-time display and detailed analysis of signal curves

- Permanent storage and export of data and graphics

- Easy operation with drag & drop and flexible formatting

- Custom trigger and recording options

- Broad utilization throughout the entire plant life cycle

Script Generator

The Script Generator transmits signal curves from the recorder or external data sources directly into WinMOD. This allows real measurement data from machine and plant components to be integrated into the simulation and, with the integrated Force Machine event-oriented playback. This enables fast and cost-effective simulation of necessary signal sequences based on real data – without any additional programming.

The Force Machine controls scriptable elements in run mode, either based on previously recorded or manually created script files. This allows even complex processes to be realistically simulated and flexibly tested.

Your approach:

- Use of existing records

- Importing data into WinMOD

- Playing back signal waveforms in the simulation

Your advantages:

- High degree of realism in the simulation

- Simple modelling of even complex processes

- Minimal effort thanks to direct data transfer

Examples:

- Real consumer profiles (e.g. electricity, water)

- Actual throughputs of sub-systems

- Actual expenditure on components

Additional libraries and add-ons

The basis of every automation project is actuators (drives) and sensors (measuring devices), for which we provide extensive libraries.

Whether liquid, gaseous or solid – the WinMOD process libraries offer technological functionalities for process modelling.

Using technology-specific 3D libraries, you can create realistic material flow simulations based on a modular principle.

From the automated project creation, about the signal recording, evaluation and comparison up to and including Play Recorded data and scenarios – intelligent assistants enhance efficiency and quality in engineering and utilisation.