Device libraries

WinMOD device libraries offer sensors, robot and electrical, hydraulic and pneumatic drives with high performance and enable efficient workflows thanks to standardised interfaces. The clear structure and modular architecture promote maximum reusability and accelerate development and integration processes.

basic drives

This library contains versatile hydraulically, pneumatic or electrically powered drives, e.g. for agitators, positioners and piece goods transport and positioning systems. In addition to control variants for OPEN/CLOSE, functions such as acceleration ramps, creep modes and discrete speed inputs are supported. All models are flexibly expandable and can be specifically adapted to your application.

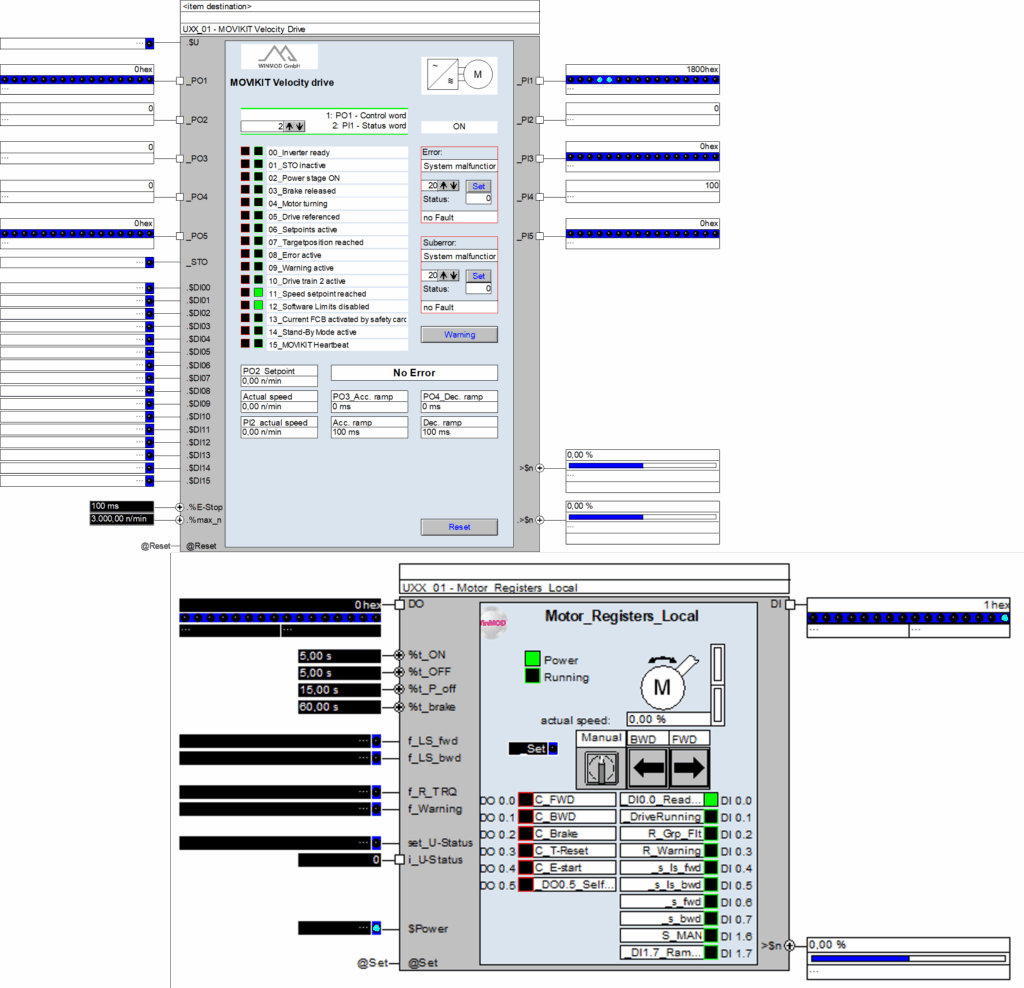

Frequency converters/servo drives

This collection includes motors that are typically controlled as bus devices via control/status words. They visualise control and status information in the control panel and offer options for different operating modes, error codes and quick stops. The models map the necessary motion behaviour, e.g. table positioning. Numerous models from ABB, AUMA, FESTO, Lenze, SEW and Siemens are available and can be adapted to your naming system.

Manufacturer-specific solutions for:

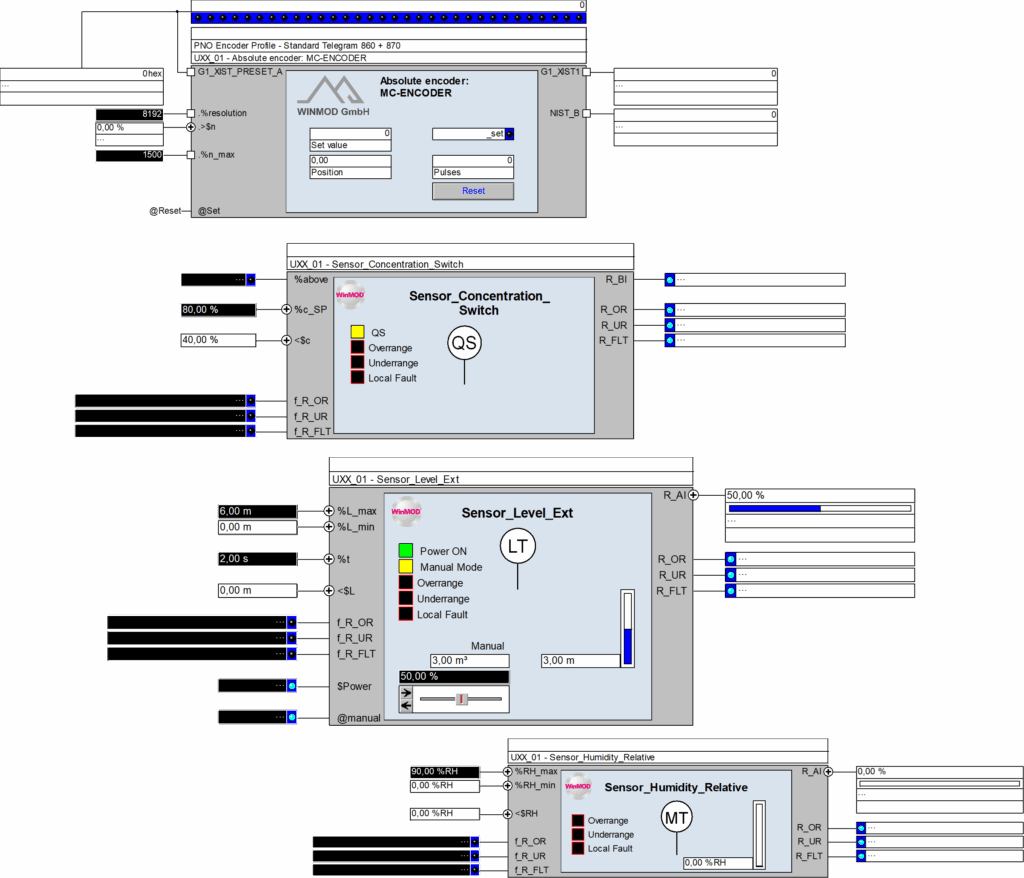

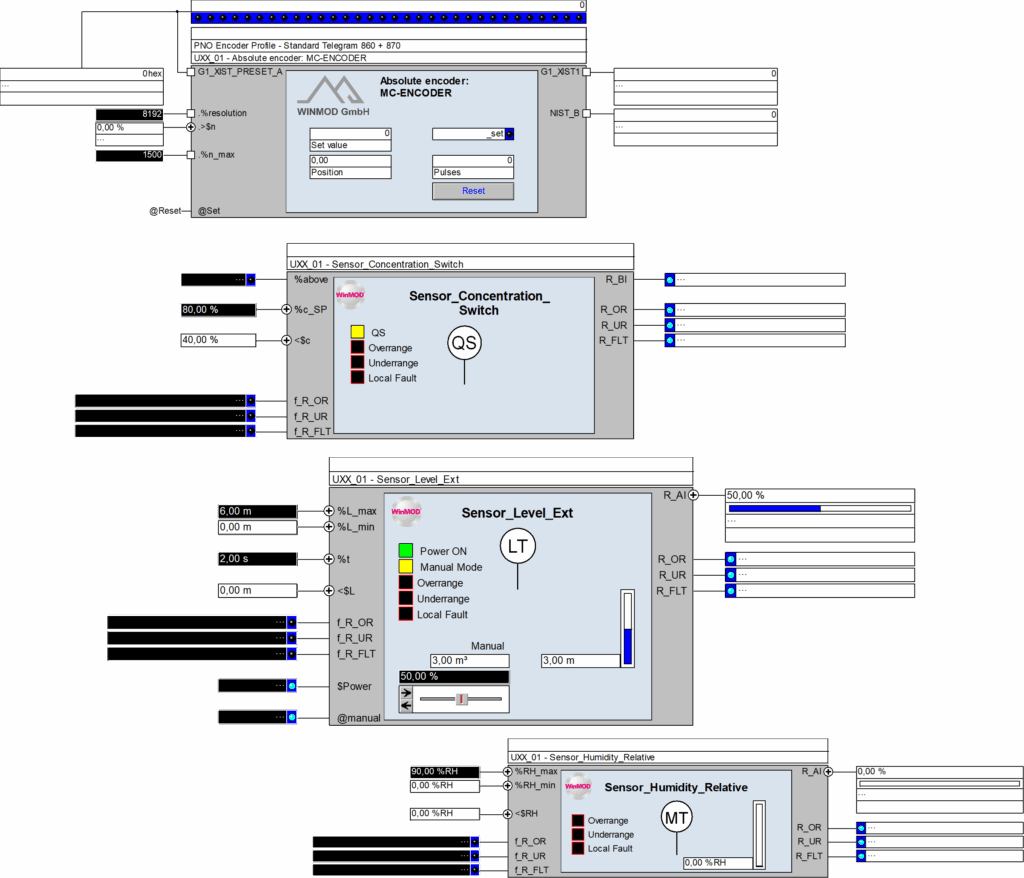

basic sensors

This provides a wide range of sensors that are indispensable for realistic simulations. It covers common use cases and supports fast, flexible project planning:

- switching contacts and limit switch enable the simple mapping of binary states.

- Continuous measurements for pressure, temperature or level and ensure precise process simulations.

- Impulses from movements or counting operations and are ideal for speed or volume measurements.

smart sensors

- encoder give Angle and position information and provide an accurate basis for motion and drive models.

Thanks to their clear structure and practical functions, the sensor elements can be quickly integrated into projects and contribute to consistent, efficient modelling. Products are available from Endress+Hauser, SENSOPART, Sick and Siemens.

Manufacturer-specific solutions for:

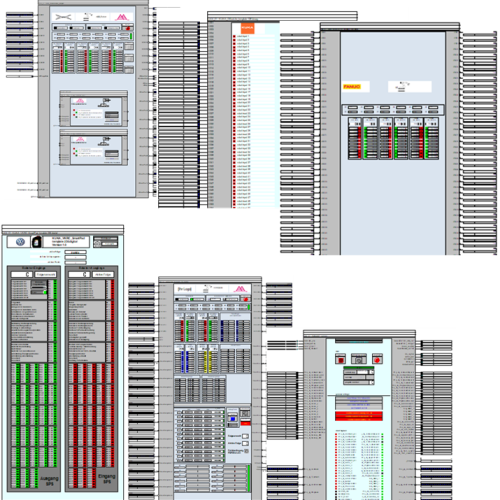

robot

The robot libraries connect to virtual controllers and simulation tools from leading manufacturers. Supported are

- ABB

- FANUC

- Kawasaki

- KUKA

- Process Simulate

- universal Robots

- Yasakawa.

This provides powerful tools for testing and optimising robot applications in a realistic environment.

With ROBCASE A manufacturer-independent solution is offered, e.g. if no robot programmes are available (yet).

Currently supported:

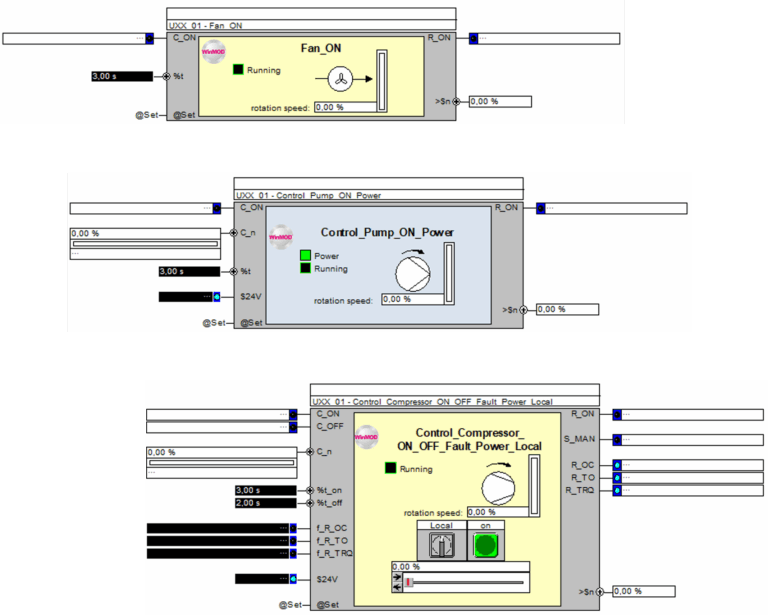

Pumps, compressors and blowers

The library contains a wide range of drives for pumps, compressor and blower – each with different control types (ON, ON/OFF), fault conditions such as overcurrent, options for power supply and control panels. This makes it easy to map practical scenarios and customise them to realistically simulate real plant behaviour.

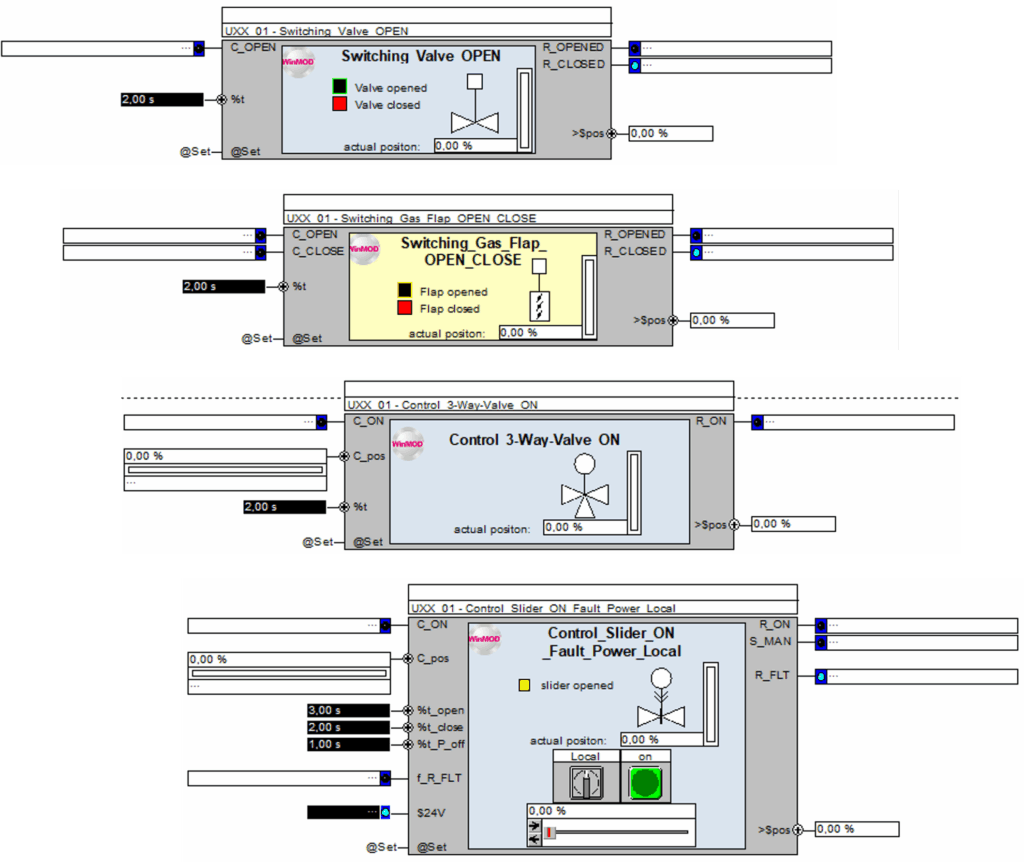

Valves and flaps

This library allows realistic simulation of hydraulically and pneumatically operated valves as well as ventilation and gas flaps – various control types (OPEN, OPEN/CLOSE, pulse) as well as typical error cases and power supplies are available. Thanks to easy editing, models can be quickly adapted to your process requirements.

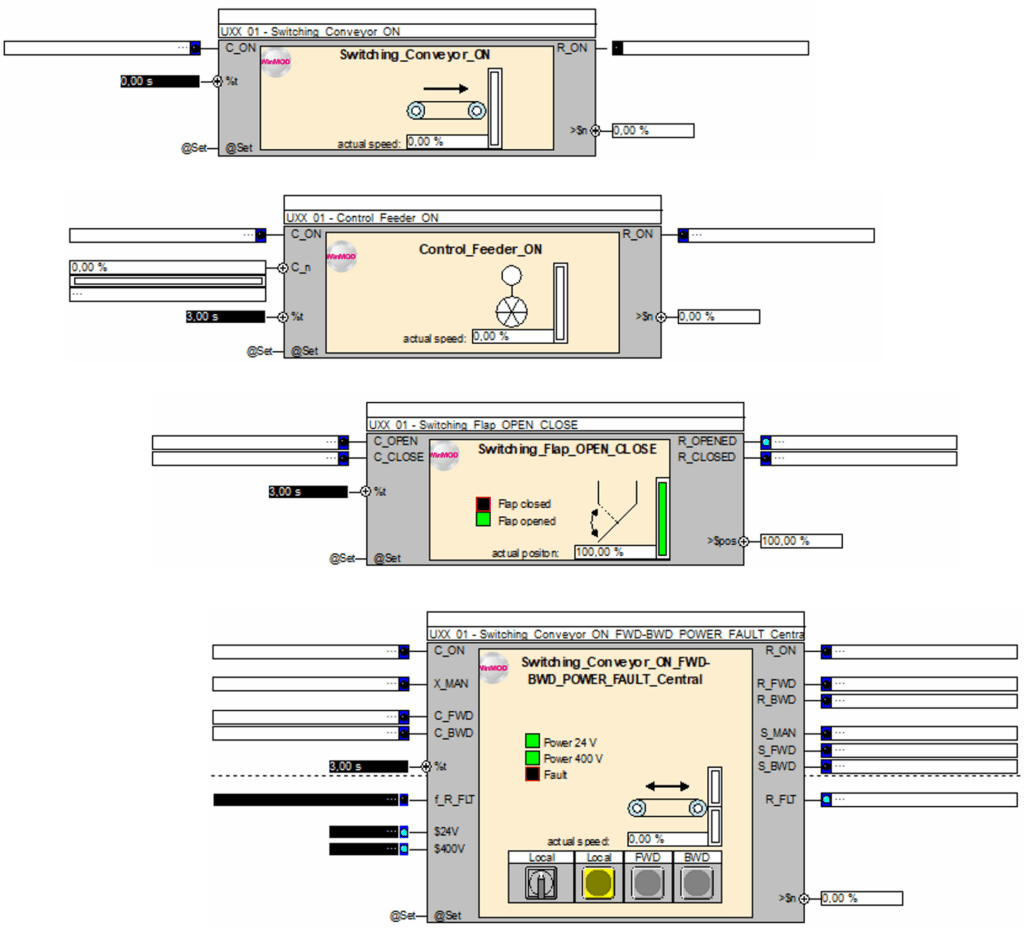

Belts, screws, sluices and flaps

This library provides versatile drives for conveyor belts, screw conveyors, rotary valves and bulk material flaps. In addition to control types (ON/OFF), error patterns, energy options and control panels are also integrated. This creates a flexible basis for efficiently simulating material flows and conveyor scenarios.

Additional libraries and add-ons

The basis of every automation project is actuators (drives) and sensors (measuring devices), for which we provide extensive libraries.

Whether liquid, gaseous or solid – the WinMOD process libraries offer technological functionalities for process modelling.

Using technology-specific 3D libraries, you can create realistic material flow simulations based on a modular principle.

From the automated project creation, about the signal recording, evaluation and comparison up to and including Play Recorded data and scenarios – intelligent assistants enhance efficiency and quality in engineering and utilisation.