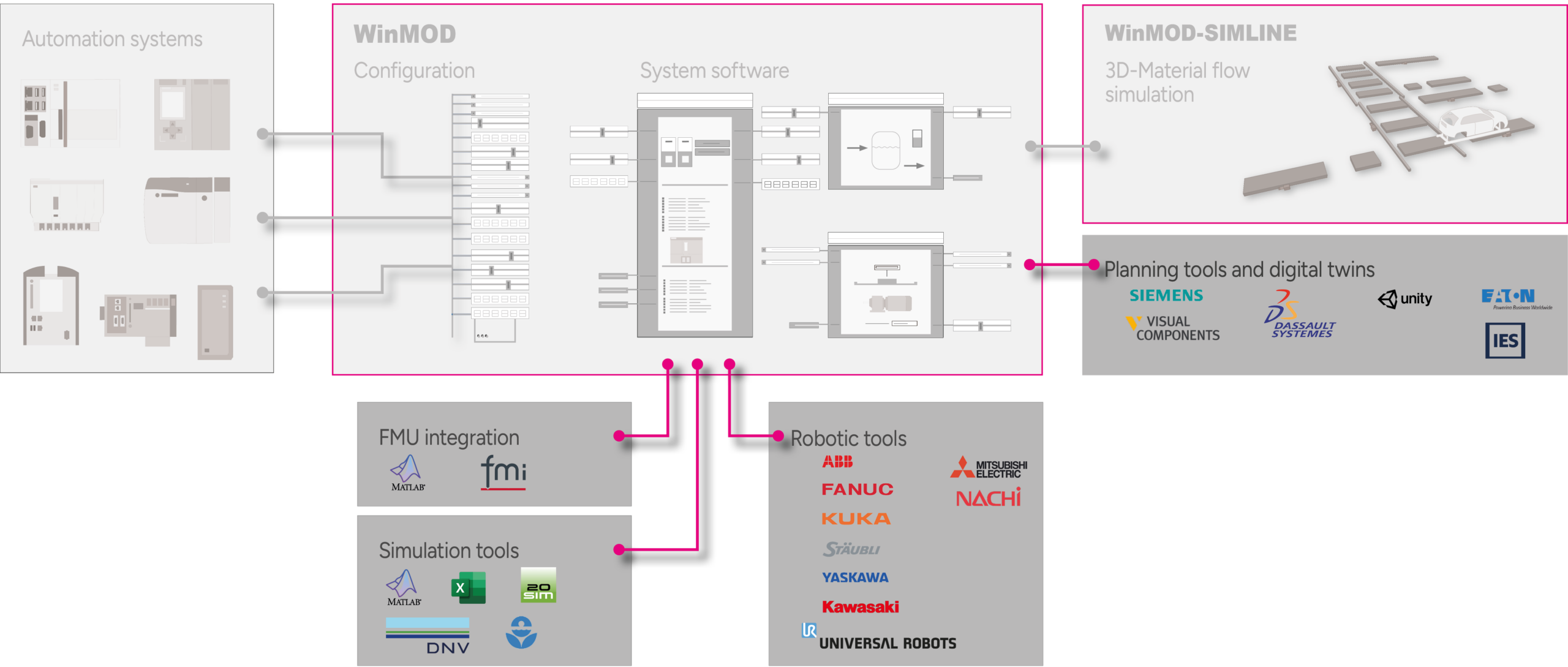

WinMOD co-Simulations

Expand your simulation with numerous integrated interfaces to the world's leading robot manufacturers, process simulators and digital planning tools – all in real time and with maximum precision.

robot manufacturer

WinMOD supports robot systems from the following manufacturers: Kawasaki, Epson, FANUC, Yaskawa, KUKA, ABB, Universal Robots, Stäubli, Comau.

These interfaces enable realistic integration of robots into your plant models, including motion sequences and signal communication for comprehensive testing.

Planning tools and digital twins

WinMOD interfaces seamlessly with leading planning simulators to map complex production processes and layouts: Dassault DELMIA 3DEXPERIENCE, Visual Components, PlantSimulation, Process Simulate / Technomatix.

This allows material flows, process sequences and automation functions to be holistically reused and validated. WinMOD thus enables the direct reuse of your planning data – without time-consuming data conversion and loss of quality. All necessary changes are made directly in the original planning data to ensure a consistent and efficient process chain. This means that no additional 3D software or special qualifications are required – saving time and costs and simplifying your workflow in the long term.

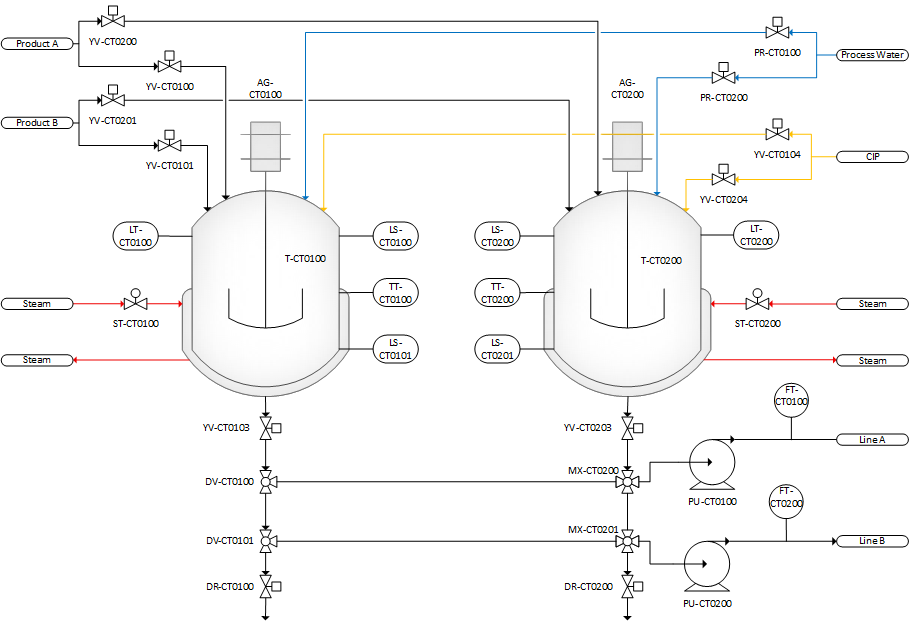

Process engineering simulations

Integrate process simulation systems such as EPANET to accurately model and analyse water distribution networks and similar systems. This integration enables detailed mapping of hydraulic processes, network analysis and evaluation of various operating conditions under realistic conditions.

Support for Functional Mockup Unit (FMU)

WinMOD offers an optimised runtime environment for standardised simulation models in FMU format according to the FMI standard. This opens up the possibility of integrating additional simulation models from systems such as MATLAB Simulink, Modellica, etc..

Currently available couplings:

Further components of the WinMOD system platform

The WinMOD system software is the core of WinMOD systems. It connects the modules of the WinMOD system platform to form an operational overall system.

WinMOD offers a powerful coupling concept for connecting real and virtual automation systems – flexible, manufacturer-neutral and future-proof.

Configurations and CoSimulation can be used to integrate automation systems and simulation tools from different manufacturers.

3D environment for real-time simulation of conveyor systems, handling processes and visualisation of machine sequences.