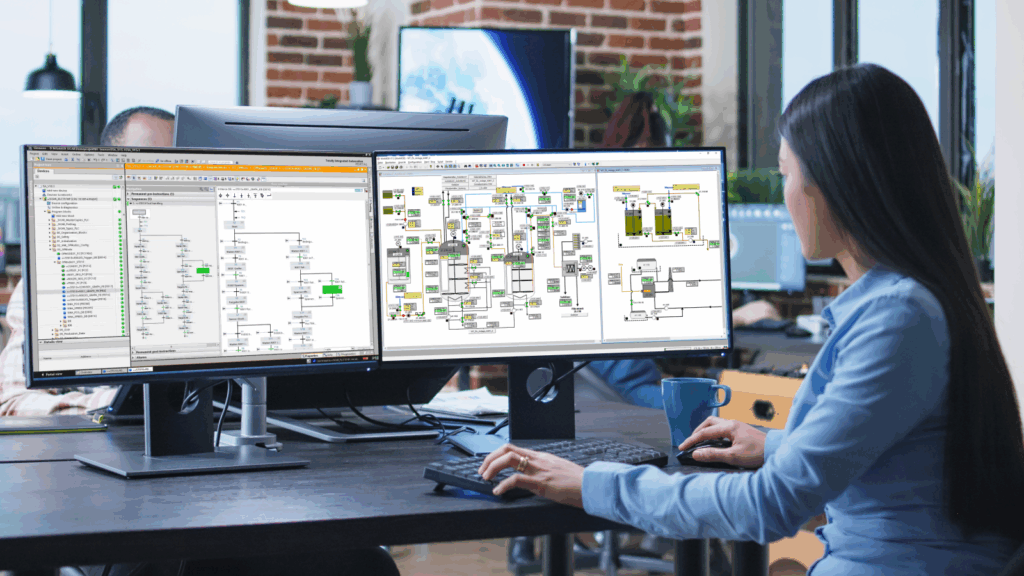

WinMOD configurations

Seamlessly connected with WinMOD couplings

WinMOD offers a powerful coupling concept for connecting real and virtual automation systems – flexible, manufacturer-neutral and future-proof.

Hardware-in-the-loop (HiL)

Real controllers can be connected directly to WinMOD – via manufacturer-neutral fieldbus emulations, mostly without special hardware. Supported protocols include: PROFINET, PROFIBUS, INTERBUS, Modbus TCP, EtherNet/IP and EtherCAT. This allows you to test real hardware in conjunction with virtual models in real time, including SAFETY and acyclic telegram traffic.

Software-in-the-Loop (SiL)

WinMOD supports coupling to PLC simulations from leading manufacturers, including: Siemens, Rockwell, B&R, Beckhoff, WAGO, Schneider Electric, Phoenix Contact, Beijer Elctronic, Moeller /Eaton, Bosch Rexroth. This enables realistic simulation of complete control systems – without any physical hardware.

PLC manufacturer-specific couplings

For particularly deep integration with access to PLC-internal signals, WinMOD offers special couplings for: Siemens, B&R, Beckhoff and Rockwell. These enable optimised communication, diagnostic functions and even closer integration with the engineering environment.

Network-based communication (TCP/IP & UDP/IP)

WinMOD also enables coupling via TCP/IP and UDP/IP – e.g. for connecting control systems, SCADA or MES applications. This allows higher-level systems to be easily integrated into the simulation.

Open system interfaces: OPC UA & OPC DA

WinMOD supports OPC UA (Unified Architecture) and OPC DA (Classic Data Access) for the integration of open or higher-level systems. This enables standardised, platform-independent communication.

Linking individual Windows applications

Your own Windows applications can be connected directly to WinMOD via API interfaces. This allows you to flexibly integrate your own tools such as visualisations and testing systems.

WinMOD couplings realise our WinMOD configurations High performance and reliability, even with large amounts of data.

Currently available couplings:

Further components of the WinMOD system platform

The WinMOD system software is the core of WinMOD systems. It connects the modules of the WinMOD system platform to form an operational overall system.

WinMOD offers a powerful coupling concept for connecting real and virtual automation systems – flexible, manufacturer-neutral and future-proof.

Configurations and CoSimulation can be used to integrate automation systems and simulation tools from different manufacturers.

3D environment for real-time simulation of conveyor systems, handling processes and visualisation of machine sequences.