battery manufacturing

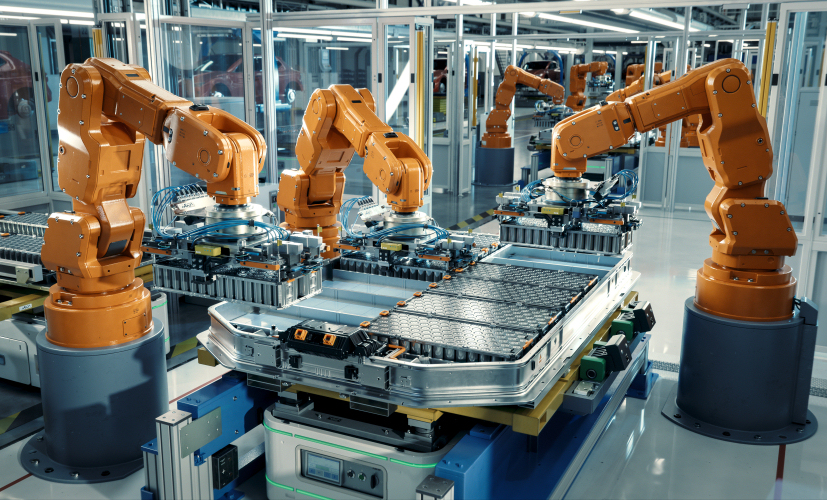

Production of traction batteries for electric cars

VC of various technologies

Battery production involves various specialised technologies, from electrode manufacturing and cell assembly to module assembly, and is undoubtedly one of the key technologies in automotive engineering today. The WinMOD-SIMLINE system allows processes such as stacking, winding, cell housing joining, laser welding, electrolyte dosing and cell assembly to be put into operation virtually. The special feature is that you can use one and the same VC system for this purpose. With WinMOD, you can easily create and test thermal management processes (heating, cooling, drying) and component assembly in a single simulation.

You can connect and test the individual workstations with their separate controls together with the higher-level system control in WinMOD. This also applies to robots that are used, for example, in the assembly of cells into complete packs. The robot behaviour is integrated here by connecting the manufacturer-specific simulation software to WinMOD – keyword: CoSimulation.

Transport systems and CAD integration

The transport systems used in battery production range from classic roller conveyors to electric overhead and floor conveyors (EHB, EBB) to Automativ Guided Vehicles (AGV). WinMOD-SIMLINE provides you with extensive 3D technology libraries for all these systems. For further information, simply visit the respective WinMOD technology page.

For virtual commissioning, use the 3D CAD data of your components. After direct import, these can then be transported, stacked, assembled and packaged in real time in the 3D simulation. Using WinMOD, you can create virtual traction batteries from these virtual cells, housings and modules and test your automation system.

Further automotive engineering solutions

Production area in which structural body parts and outer skin parts are produced from sheet metal coils or cut-to-size blanks (blanks) by cold or hot forming – from the raw blank to the ready-to-install formed part.

Assembles stamped/formed sheet metal parts, extruded and cast components into a dimensionally accurate body structure – with defined geometry, rigidity, crash and NVH performance as the basis for the paint shop and final assembly.

Highly automated plant chains for surface pre-treatment, coating and curing of car bodies and add-on parts – designed for high throughput, reproducible appearance and corrosion protection.

Pre-assembly of front/rear axle modules as carriers for chassis, steering and drive units such as combustion engines, powertrains or electric axles. Transport to the sequenced handover to the „marriage“ with the body.

Highly automated process chain for the fabrication of traction batteries – from electrode production to cell assembly and forming to module/pack assembly

This area of technology encompasses conveyor systems that transport and sort pallets and mesh boxes containing automotive components. The conveyor elements are large roller and chain conveyors combined with lifting, rotating and shifting tables.

Fully automated high-bay warehouses, which are operated by light or heavy-duty storage and retrieval machines and controlled by distributed automation systems. Warehouse management systems generate the orders for storing and retrieving raw components or complete car bodies.

Ground-based conveyor technology in which car bodies or heavy modules are transported on standardised SKIDs (steel frames with vehicle-specific support points) through assembly, paint shop and buffer areas.

Overhead conveyor systems with electrically driven, individually controllable trolleys on monorail tracks for low or high loads (up to tonnes).

Ground-based conveyor technology in which car bodies or heavy assemblies are moved on platforms along rails. The drive is typically provided by friction wheels, push chain conveyors or push beams, which continuously push the SKIDs forward.